Fiber optic handpiece

Dr. Michel Rechtman Paris, France I work 5 days a week in different offices in France,

I need to be able to rely on my equipment, That is why I choose JINME dental.

J6

Technology & Function

100% zero retraction prevents cross-infection, extends durability

Polarity-free

Only 46g in weight

German ceramic bearings

J6

Fiber optic handpiece

Specifications

Model

J6-136

Product name

Dental High Speed Turbine Handpiece

Order code

130159

Working pressure

0.23~0.25MPa

Rotating speed

>300krpm(Recommended Working Pressure )

Noise

≤80dB

Working water pressure

200kPa~400kPa

Water flow

≧50m/min

Radial vibration

≤0.03mm

Surface

Titanium plating

Water spray

Triple spray

Chucking type

Push-button type

Cartidge

Exposed cartridge

Bearing

German ceramic bearing

Autoclave

134 °C sterilization

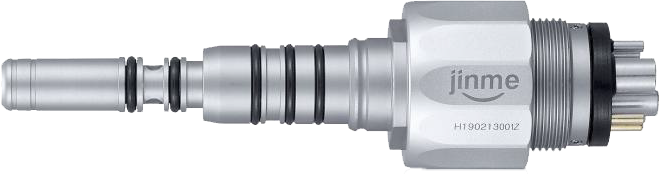

Connection

6 holes coupling(M6)

| Specifications | |

|---|---|

| Model | J6-126 |

| Product name | Dental High Speed Turbine Handpiece |

| Order code | 106102 |

| Working pressure | 0.23∼0.25 MPa |

| Rotating speed | 200 kPa∼400 kPa |

| Noise | ≤80 dB |

| Working water pressure | 200 kPa∼400 kPa |

| Water flow | ≥50 mJ/min |

| Radial vibration | ≤0.03 mm |

| Surface | Titanium plating |

| Water spray | Triple spray |

| Chucking type | Push-button type |

| Cartridge | Exposed cartridge |

| Bearing | German ceramic bearing |

| Autoclave | 134 °C sterilization |

| Connection | 6 holes coupling(M6) |

A dental high-speed handpiece is a critical tool in modern dentistry, playing a pivotal role in improving the precision, efficiency, and overall quality of dental procedures. With the ability to operate at speeds of up to 400,000 RPM (revolutions per minute), these handpieces are essential for performing intricate tasks such as cavity preparations, crown shaping, and polishing teeth. The high-speed operation allows for rapid cutting and minimal discomfort for patients, reducing the time spent in the dental chair while enhancing overall treatment outcomes.

One of the key features of a high-speed handpiece is its powerful motor, which drives the rotation of the bur (the tool used for cutting and shaping teeth). The bur is typically made of diamond or tungsten carbide, materials that can withstand the high forces generated during operation and provide precise, smooth cuts. The high speed of the handpiece ensures that the bur operates with minimal resistance, allowing dentists to remove tooth structure quickly and efficiently while maintaining accuracy.

A critical advantage of the dental high-speed handpiece is its ability to offer fine control during procedures. The tool’s lightweight, ergonomic design allows dental professionals to maneuver it with precision, ensuring that delicate work can be carried out with minimal effort. Furthermore, these handpieces are designed to reduce vibrations, which can often lead to operator fatigue and discomfort. As a result, dentists can perform longer procedures without compromising accuracy or comfort.

In addition to its high-speed operation, most modern handpieces are equipped with advanced cooling systems that help prevent overheating. These cooling mechanisms, typically a combination of water spray and air jets, maintain the temperature of the bur and the surrounding area, minimizing the risk of thermal injury to both the patient and the instrument. The cooling system also helps prolong the lifespan of the handpiece by reducing wear and tear caused by excessive heat buildup.

Another notable benefit of the dental high-speed handpiece is its quiet operation. Although these handpieces operate at high speeds, they are engineered to minimize noise, providing a more comfortable experience for patients. The reduction in noise levels helps create a less intimidating environment for patients, particularly those who experience anxiety or fear about dental visits. Moreover, the quieter sound enables the dental team to communicate more effectively during procedures.

Durability is another key aspect of high-speed handpieces. These tools are typically constructed from high-quality materials such as stainless steel or titanium, ensuring that they can withstand the demands of daily use in a busy dental practice. With proper maintenance, which includes regular cleaning, lubrication, and sterilization, dental high-speed handpieces can serve for many years, providing excellent value for dental professionals.

In terms of maintenance, it is essential to keep the handpiece in optimal working condition. Regular cleaning and sterilization are necessary to prevent the buildup of debris and bacteria, which can lead to cross-contamination between patients. Additionally, periodic lubrication of the motor and internal components is required to ensure smooth operation and prevent wear. Dentists should also inspect the handpiece for any damage or malfunction, such as worn-out bearings or loose parts, to prevent performance issues and ensure the safety of both the patient and the dental team.

In summary, the dental high-speed handpiece is an indispensable tool that enhances the speed, precision, and comfort of dental procedures. Its high RPM, ergonomic design, advanced cooling systems, and durability make it a vital part of any modern dental practice. As technology continues to advance, high-speed handpieces are expected to incorporate even more innovations that will further improve dental care, making it more efficient, accurate, and comfortable for both patients and practitioners.

19th Floor, Wanyang Technology Co-Innovation City, Shishan Town, Nanhai District, Foshan City, Guangdong Province, China

Tel:

0086 757 88777997

Email:

info@jinmedental.com